Machining procedures, which include the deliberate removal of material to shape, cut, or finish a workpiece, are crucial to the manufacturing process. Common operations include turning, which involves forming a spinning workpiece with a stationary cutting tool; milling, which involves creating a variety of forms using rotary cutters; drilling, which creates holes; and grinding, which produces exact surface finishes.

While honing improves surface polish, electrical discharges are used in Electrical Discharge Machining (EDM) to degrade material. These procedures are automated with more accuracy and efficiency thanks to cutting-edge CNC technology. Intricate components for a variety of sectors are created by machining processing, which is essential for producing high-quality parts that are accurate and repeatable.

Kinds of Machining Operations Are Most Common

Complex and unique additives for a range of industries are produced in modern production mostly through the use of machining processes. One way to get particular floor finishes, shapes, and sizes with these techniques is to remove cloth from a project.

Turning

A workpiece rotates during the basic machining process of turning, which takes material from it to form cylindrical shapes with a cutting tool. Fasteners like bolts, bushings, and shafts are frequently made using this procedure. CNC lathes, or computer numerical control, have completely changed the turning industry by providing accurate and automated control over the movements of the cutting tool.

Milling

Using a revolving cutter to remove material from a workpiece, milling is a versatile machining method. In contrast to turning, milling is capable of producing a large variety of features and shapes, such as intricate curves, pockets, and slots. Due to their exceptional accuracy and productivity when creating complex components, CNC milling machines have become essential in today’s industrial processes.

Drilling

One of the main machining processes is drilling, which is used to make holes in a workpiece. A revolving drill bit exerts pressure on the workpiece, eliminating material and resulting in a hole with the required diameter. The placement and size of holes can be done accurately and consistently by using CNC drilling equipment.

Crushing

Using an abrasive wheel to remove material and obtain a smooth surface finish is the precision machining process known as grinding. To create tight tolerances and improve the dimensional accuracy of components, this method is essential. Some popular variations of this procedure are surface grinding, cylindrical grinding, and centerless grinding.

Electro-magnetic discharge machining, or EDM

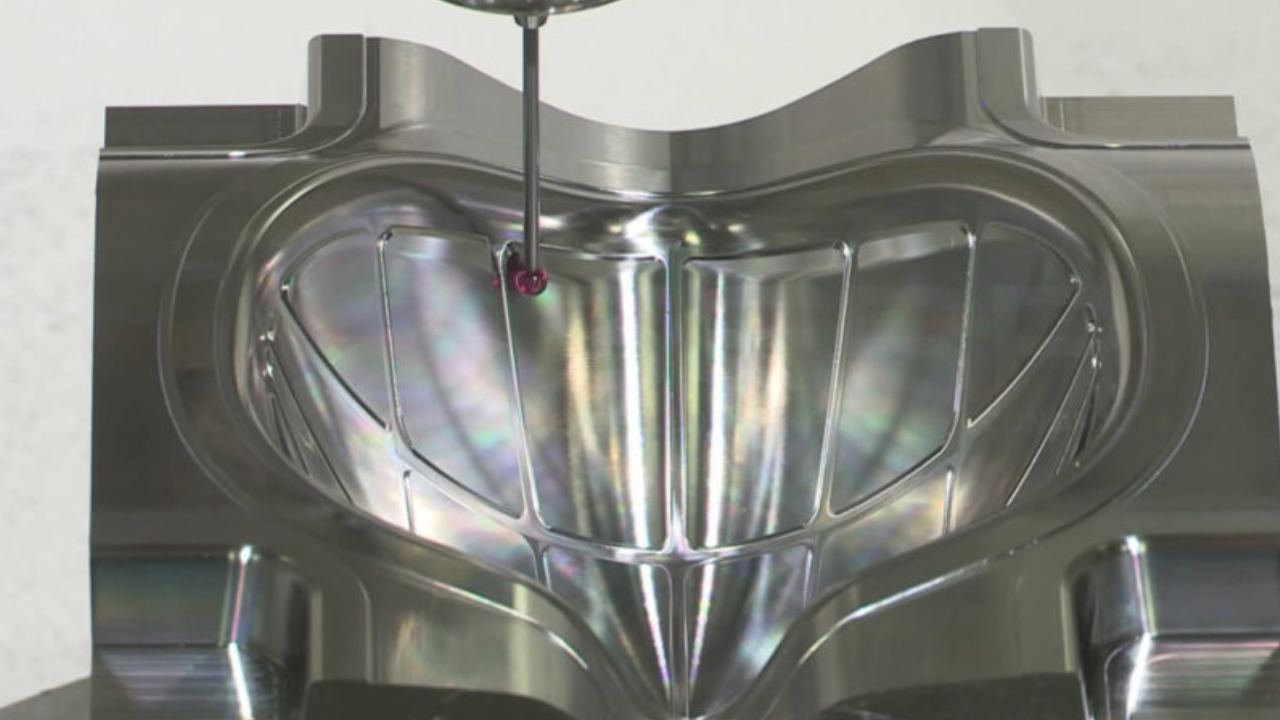

Using electrical discharges to remove material from a workpiece, EDM is a non-traditional machining technique. It works especially well for cutting materials like hardened steels and unusual alloys that are difficult to machine using traditional techniques. Intricate tooling dies, and molds are produced using EDM.

Reaching Out

In the machining process known as broaching, material is removed linearly with a toothed tool. It is frequently employed to create splines, keyways, and other complex features. There are several varieties of broaching machines, including surface, vertical, and horizontal models, and each is appropriate for a particular use.

Sharpening

A finishing technique called honing enhances a machined part’s geometry and surface polish. It makes use of abrasive stones that oscillate and move in a controlled manner across the workpiece’s surface. To achieve exact proportions and a high-quality surface finish, honing is essential.

Centers for CNC Machining

CNC machining centers offer a high level of automation and versatility by combining several machining operations into one device. The creation of complex components requires the use of these centers since they can carry out tasks like drilling, tapping, and milling without the need for manual assistance.

Using CNC Plasma Cutting

To cut through electrically conductive materials, mostly metals, CNC plasma cutting machines use a high-velocity stream of ionized gas. This method produces precise and complex shapes and is frequently used in the aerospace, automotive, and metal production industries.

EDM Wired

A thin, electrically charged wire is used to cut through a workpiece in a process known as wire EDM, a variation in electrical discharge machining. In the production of tools and dies, this extremely precise method is frequently used to create complex forms and profiles.

Conclusion

Today’s manufacturing is based mostly on machining methods, which allow a wide range of sectors to produce complex and precise components. The machining processes are constantly evolving because of the progress made in CNC technology, which gives manufacturers the means to remain at the forefront of efficiency and innovation in the highly competitive manufacturing sector.